IBR Integrated Sewage Equipment

Introduction to IBR Self-Response Bioreactor:

1. Overview of the IBM process

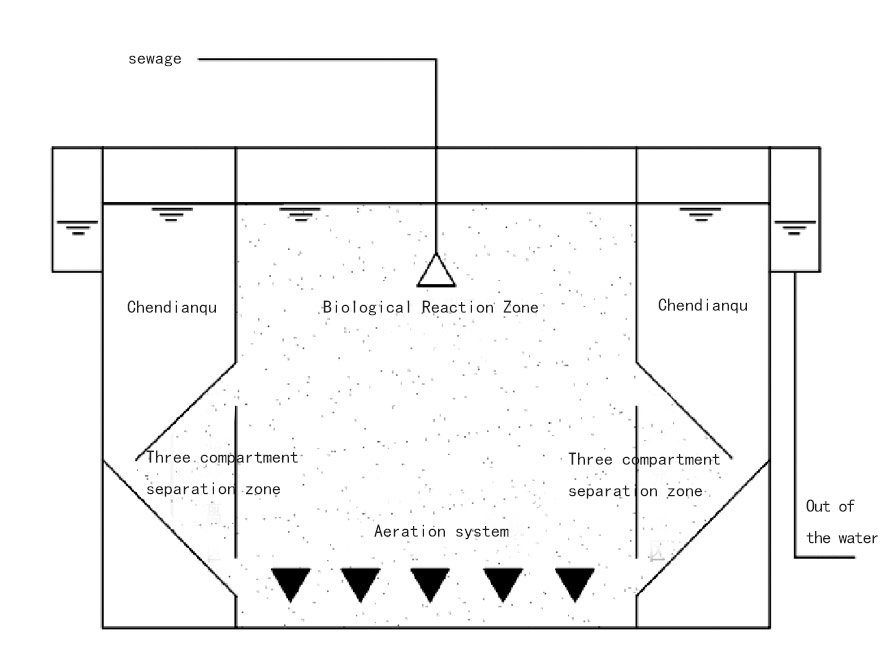

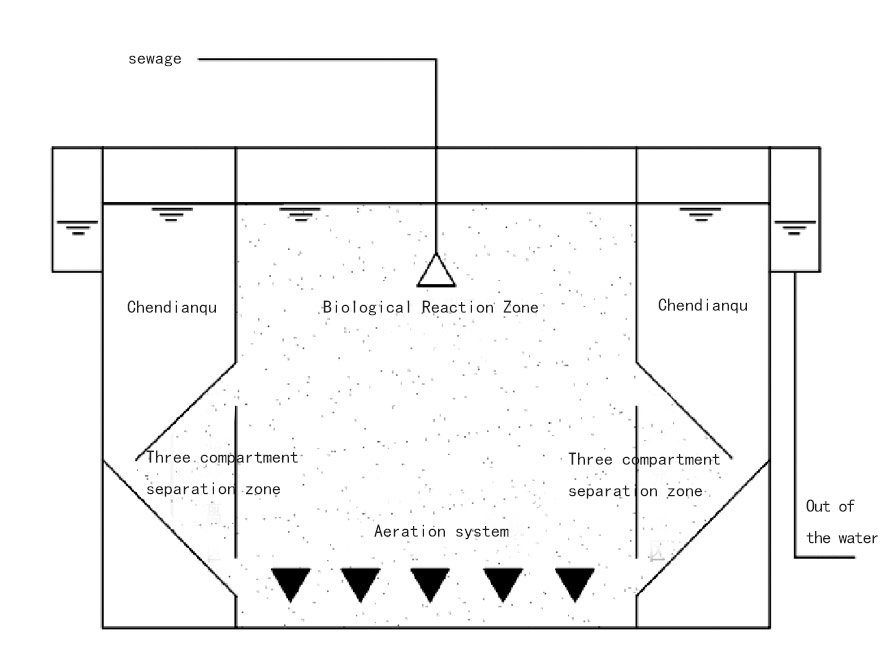

IBR reaction pool base structure

|

首页 > English > Product > Integrated equipment > |

IBR Integrated Sewage Equipment Introduction to IBR Self-Response Bioreactor: 1. Overview of the IBM process

IBR(Intermission Biological Reactor), a self-response bioreactor, is an anaerobic, CO-oxygen, aerobic reaction and precipitation in a cycle of activated sludge, is a modified version of the regular SRB(Sequencing Batch Reactor) process.

The IBR process has the characteristics of less structure and equipment, less land saving, low energy consumption and running cost, simple control and noise-free operation.

1.1 Process Fundamentals

The IBR self-response bioreactor uses the three-phase separation device at the lower part of the equipment to realize continuous intake and discharge of single pool and intermittent aeration. By adjusting the aeration stop pen, the multi-level A/A / O state of the reaction tank was constructed, and the optimal condition was achieved to remove nitrogen and phosphorus effectively. In the process of operation, the aeration ratio can be adjusted according to the condition of water quality, water quantity, temperature and season, so as to achieve the best amount of aeration and reach the system

IBR reaction pool base structure

The reactor can be divided into reaction zone, three-phase separation zone and precipitation zone, and the whole reactor is in a continuous flow integrated configuration. The core equipment and device are shock wave mass carrier(aeration, stirring function), three-phase separator(precipitation, drainage function).

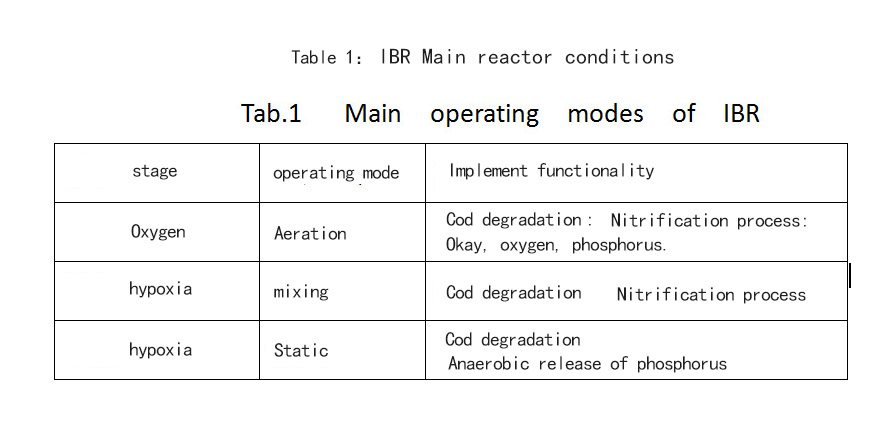

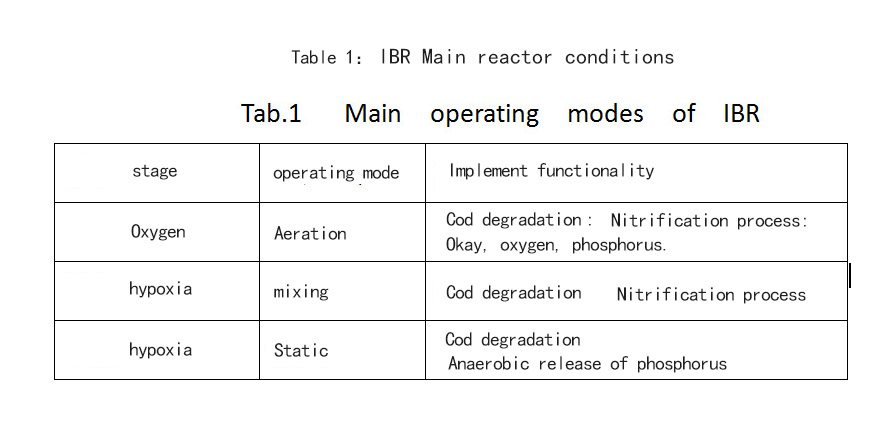

The IBR reaction pool is mainly based on time series to realize the efficient removal of nitrogen and phosphorus from wastewater.

1.2 Process Design Principles

The IBR process is based on the conventional SBR process principle and relies on a variety of techniques: The reactor shape is based on the structure characteristics of integrated oxidation ditch and UASB reactor. The mechanism of action refers to conventional aeration deposition technology, A2/O and chemical enhanced phosphorus removal technology. The working characteristics of the critical equipment shock wave transmitter are similar to that of the two stage jet aeration device and the two-jet concealed mixer.

1.3 Analysis of Process Characteristics of IBR

The IBR process is a kind of batch activated sludge method. Although the reaction pool is fully mixed in flow state, it is a time-pushing flow in organic degradation. The main technical features of the process are summarized below:

Less structure and less land

Due to its continuous water flow characteristics, IBR reactor can be easily combined with advection sand sink and subsequent disinfection channels for smaller scale domestic sewage treatment. The process is well arranged, simple in plane and economical in land

IBR process needs to be equipped with a relatively simple electromechanical equipment, the structure only needs to be equipped with shock mass transfer equipment and so on a small number of equipment, the power equipment in the system only submersible pump and mixing equipment, the energy consumption is very low. At the same time, the sewage treatment process of lifting water head decreased by more than 1 m compared with other time series because of the continuous water flow in and out of IBR pool.

Simple control, few process equipment

The shock transducer and submersible mixer in the IBR reaction pool can only be controlled by time, without complicated feedback and actuating elements. Therefore, the process system can be controlled by simple time control and liquid level control device, and the operation management is simple.

There is no noise running

The power equipment in the system is only submersible pump and mixing equipment, no noise generating power equipment, the whole system is in silent operation state, no noise pollution to the environment.

IBR Integrated Sewage Equipment 2018/04/16 Views Times

Related products |

|

||||||||||||||

zhongqiao environnmental sclence The main production:Integrated sewage treatment equipmentAir flotation machine Mud scraper |

||||||||||||||